What is aerated concrete?

Aerated concrete is a light wall mesh material that has become the choice of construction in the modern world.

High-performance aerated concrete is preferred in construction in the majority of big cities in the modern world. Thanks to the increasingly common use of aerated concrete, the building loses its wall load and increases its resistance to earthquakes. It also makes an important contribution to the thermal insulation of buildings by means of an important insulation element. The reason for this is that the gas conductivity is the lowest heavy wall material.

GASBETON PRODUCTION

Aerated concrete silica sand, which is a building material entering into light concrete group, is produced by mixing with water together with cement and lime which are used as binder. The resulting paste after adding the aluminum paste which causes gas to form. This paste is poured into steel molds and cut to desired dimensions with millimeter precision and subjected to steam curing to harden.

GASBETON USAGE AREAS

Lightweight, porous and also resistant to high pressure, the aerated concrete can be processed easily and it can enter all the desired geometric shapes. It is used safely in all private and state buildings as heat insulation plate and asmolen blocks.

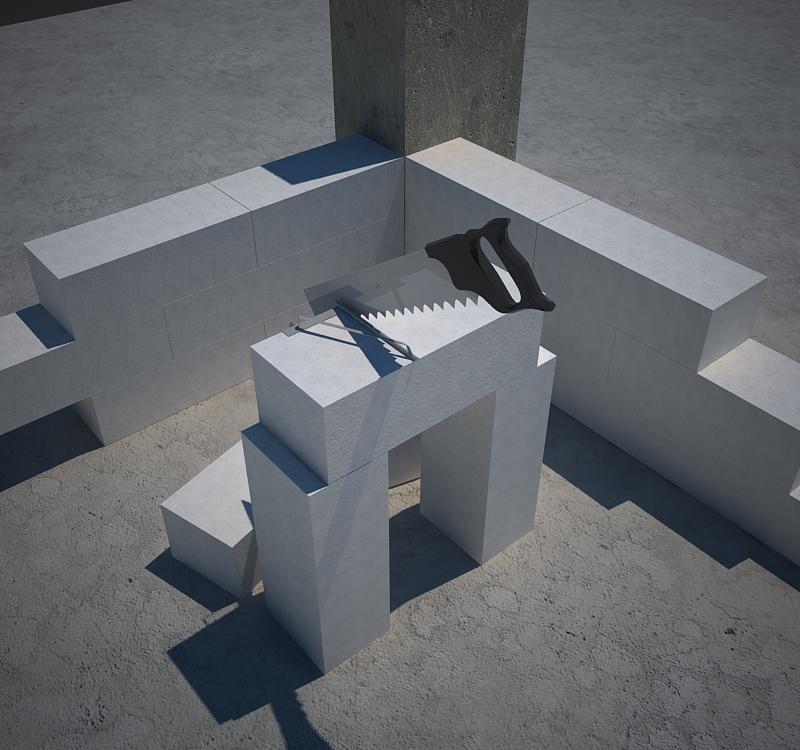

GASBETON PROCESSING IS EASY

It can be cut to the desired size with cutting tools and provides great convenience in proper walling. It also saves labor time and cost.

GASBETON IS RIGHT AND LONG LIFE

As it has a closed structure, it absorbs less water and moisture. Thanks to its inorganic and massive structure, it is more durable and durable. It is more resistant to climate and environmental conditions.

GASBETON IS MORE INVESTED

Thanks to the aerated concrete, construction work is reduced by a significant amount and a chance to make a clean wall.

THERMAL INSULATION

Aerated concrete which provides 3 times more heat insulation than concrete 10 and perforated brick provides a significant saving in heating costs. Thanks to its porous structure, it prevents the outside cold to leak inside. It does not harm the environment due to the materials used in its construction while providing thermal insulation.

GASBETON FIRE RESISTANT

Thanks to its inorganic structure, it is fire resistant up to 1000-2000 degrees and it provides fireproof, fireproof structures.

GASBETON HAS HIGH RESISTANCE

Cement and Lime is used in the construction of gas concrete has a lot of durability.

GASBETON'S SOUND INSULATION IS PERFECT

In addition to thermal insulation, it is very effective in sound insulation. Due to its structure, it can keep the sound out by making less noise.

GASBETON RESISTANT AND EARTHQUAKE RESISTANT

It is more resistant to earthquake because it is light. In addition, the building's transport system with less load thrust thanks to the protection of the building at the time of the earthquake.

OTHER NEWS

Exterior Paint TypesMar 4, 2019

Acrylic copolymer binder based top coat exterior paint.

More

Thermal Insulation SystemsŞub 20, 2019

In the summer heat loss in buildings is to cover the outer or inner shell of the building with heat insulation materials to prevent heat gains.

More

Advantages of Suspended CeilingŞub 14, 2019

Nowadays, while the health and hygiene conditions are aggravated, it is expected that the buildings will fully comply with these issues.

More